Mobile:18928206361

Telphone:0769-82586018

Fax:0769-81668689

E-mail:1397309359@qq.com

Ultra-low noise:

Adopt high precision gear hobbing machine and AAA high-grade hob machining high precision spiral bevel gear, precision up to IT5 ~ 6;

This precision CNC machining, concentricity, high position precision of IT6;

Double column form of high rigidity structure when using the four corners of the box body, even under high load conditions and solid deformation, small vibration.

Super long life:

Molybdenum containing high alloy steel and special heat treatment using this gear material of the gear form rigid toughening and wear collapse teeth;

All equipment ball bearings -- gear box;

The Grayson spiral structure -- right angle gearbox, transmission torque, bearing capacity of up to 2 ~ 3 times of ordinary products, durable;

Advanced nano antiwear grease filling -- gear box.

High reliability:

Only through the electromagnetic system design of computer optimization, the motor of high efficiency, low temperature rise;

Adopt H (180 C) enameled wire and insulation materials, high safety margin;

When using low loss silicon steel sheet and the development of precision stamping technology, high precision, small loss.

Easy installation:

When the gearbox uses internal thread installation standards, and embedded in the stainless steel screw set, the installation is convenient, the thread is not easy to damage;

When the output shaft bearing with gear box to cancel the boss, can be directly installed close to the surface of the installation, no longer need to install on the surface of large hole processing trouble.

Safe and beautiful:

No grade IP54 mini type connection box protection, wiring and replacement is more convenient and safer, more beautiful, more clean, make your products better meet safety standards;

We can provide the products comply with certification, safety and security;

Only after special processing surface spraying senior Royal Blue Regent paint, more delicate and luxurious.

Model diversity:

Only with strong capital and technical strength, motor frame size: 60 ~ 100, power: 6W ~ 200W, the full range of 620 models, and the torque of the motor, standard, rectangular hollow and rectangular solid reducer;

It is equipped with powerful governor and electronic brake panel with DIN built-in variety, more auxiliary angle mounting foot, flexible coupling, convenient customer selection, realize one-stop purchase;

It is easy and convenient, save money and effort.

Introduction of JSCC fine grinding machine:

Motor power: 6W-15W-25W-40W-60W-90W-120W-200W

Single phase voltage: 100V-110V-115V-120V-127V-220V-240V

Three-phase voltage: 200V-220V-230V-240V-380V-400V-415V-440V

Voltage frequency: 50HZ/60HZ

Reduction ratio: 1/3-1/1800

Output speed: 0.1-1450RPM

Output torque: 0.1-120N.m

Motor function: standard constant speed motor - reversible constant speed motor - adjustable speed motor - electromagnetic brake motor -

Adjustable speed electromagnetic brake motor torque motor

-

JSCC constant speed, speed regulation, brake motor

JSCC constant speed, speed regulation, brake motor

-

JSCC fine grinding SF speed regulator

JSCC fine grinding SF speed regulator

-

JSCC- precision standard motor

JSCC- precision standard motor

-

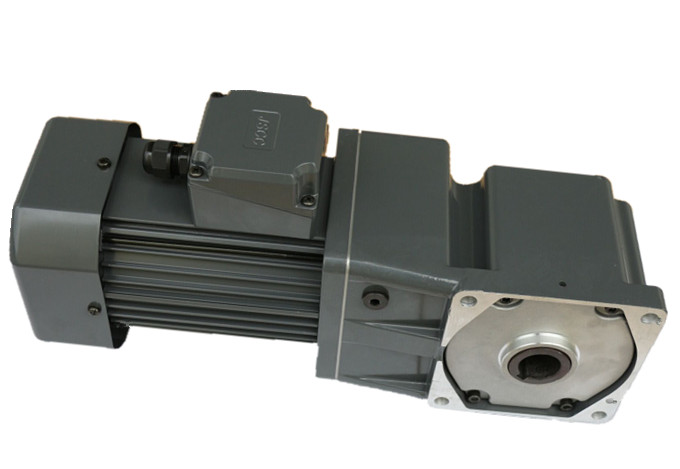

JSCC grinds standard motor + right angle hollow reducer

JSCC grinds standard motor + right angle hollow reducer

-

JSCC fine grinding gear reducer motor

JSCC fine grinding gear reducer motor

-

JSCC fine grinding large gear hollow reduction motor

JSCC fine grinding large gear hollow reduction motor

-

JSCC fine grinding motor

JSCC fine grinding motor

-

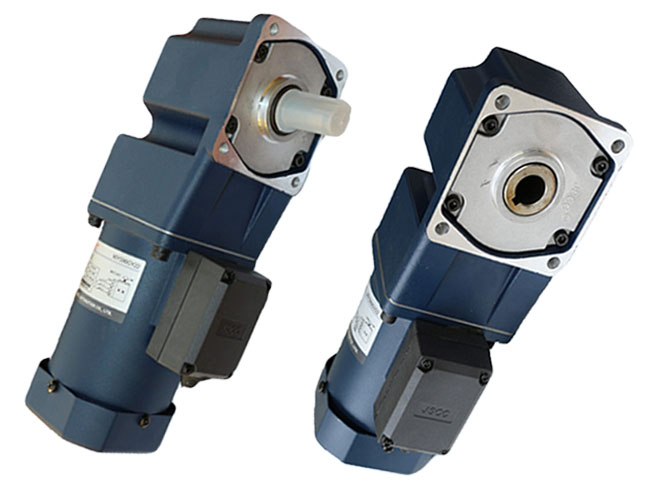

JSCC fine grinding right angle hollow reduction motor

JSCC fine grinding right angle hollow reduction motor

-

Fine grinding YS constant speed motor + reducer

Fine grinding YS constant speed motor + reducer

-

JSSS built-in governor SK200E

JSSS built-in governor SK200E

-

JSCC timing motor with right angle middle right angle hollow reducer

JSCC timing motor with right angle middle right angle hollow reducer

-

JSCC grinding angle middle solid motor

JSCC grinding angle middle solid motor

- 2016-09-14How to care for small electric hoist

- 2016-09-12Analysis of medium voltage inverter mark…

- 2016-09-10Three trends of small motor manufacturin…

- 2016-09-09Drive mode of motor

- 2016-09-083 basic ways to improve the heat dissipa…

- 2016-09-07Is the brake motor the same type as the …

- 2016-09-06Attention to the specifications and type…

- 2016-09-05Space analysis of the development of spe…

- 2016-09-02Method for preventing motor noise

- 2016-08-30Types of motors